Home /Gamma Radiation

Gamma radiation is a high-energy electromagnetic wave generated by the decay of the radioisotope Cobalt-60. Known for its exceptional penetration capability, gamma radiation can effectively treat products in dense or bulk packaging, including palletized goods. It ensures complete sterility of both final packaged products and raw materials in a safe, reliable, and proven method.

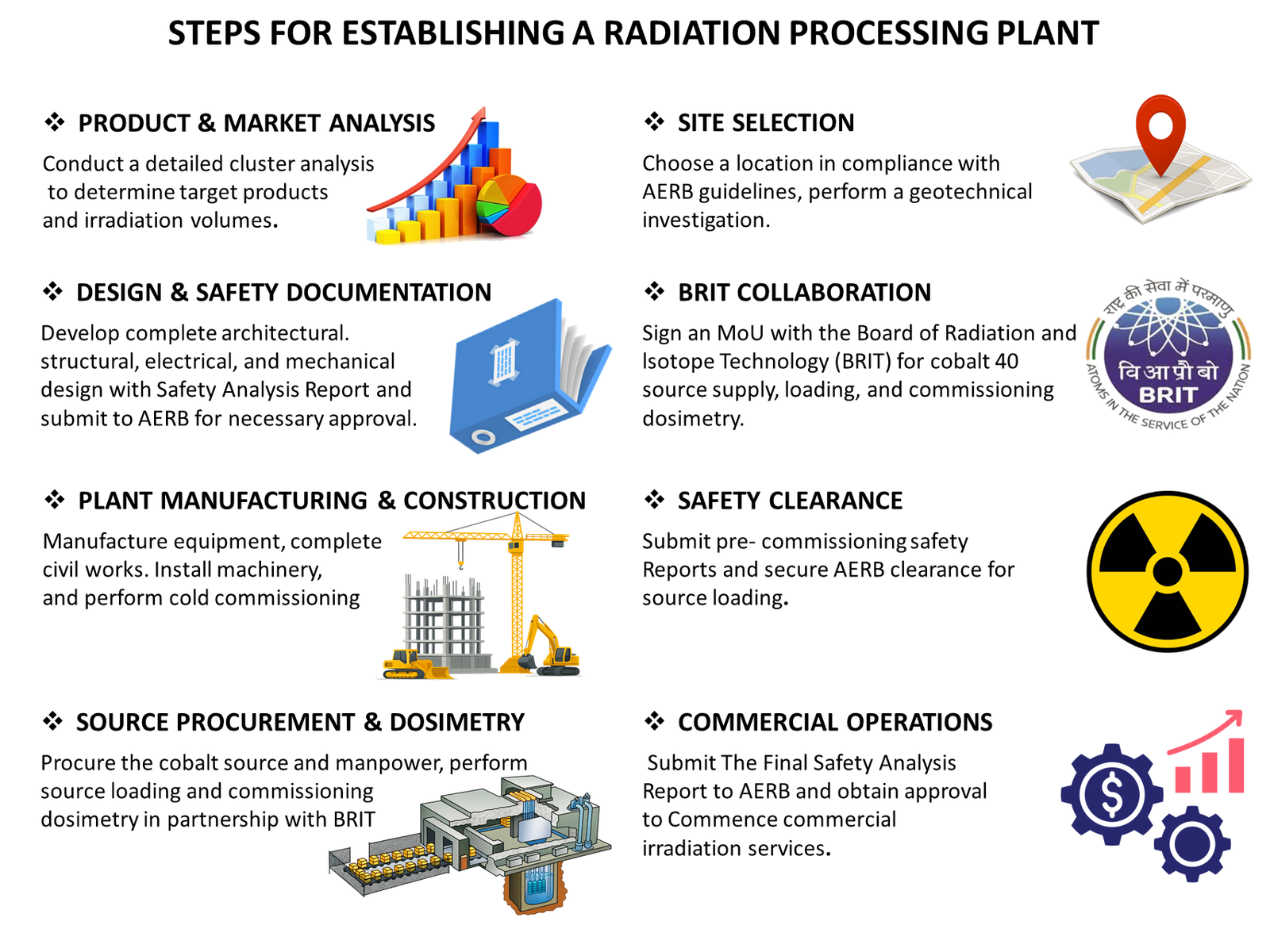

Conduct a detailed cluster analysis to determine target products and irradiation volumes.

Choose a location in compliance with AERB guidelines; perform a geotechnical investigation.

Develop complete architectural, structural, electrical, and mechanical designs with Safety Analysis Report and submit to AERB for necessary approval.

Sign an MoU with the Board of Radiation and Isotope Technology (BRIT) for cobalt-60 source supply, loading, and commissioning dosimetry.

Manufacture equipment, complete civil works, install machinery, and perform cold commissioning.

Submit pre-commissioning safety reports and secure AERB clearance for source loading.

Procure the cobalt source and manpower, perform source loading and commissioning dosimetry in partnership with BRIT.

Submit the Final Safety Analysis Report to AERB and obtain approval to commence commercial irradiation services.

We excel in the conception, design, and construction of Gamma Radiation Plants. Our turnkey

projects deliver world-class standards, ensuring customer satisfaction. Maximum throughput: 26 cumtr per hour for 25KGy dose, and 24 Ton per hour for low-dose products.

Precision Irradiation for Scientific Progress.

At Devaki Hydromatics, we design and manufacture Dry Storage Irradiators that combine reliability, safety, and scientific accuracy. Built for research laboratories and R&D facilities, these systems deliver consistent exposure while maintaining the highest standards of radiation safety and operational efficiency.

High-Capacity Systems for Industrial Impact

Our panoramic wet storage irradiators are purpose-built for large-scale industrial applications such as healthcare, sterilization, and food preservation. With advanced source handling and panoramic exposure, these units deliver precision at scale while ensuring global safety compliance.